Exploration & Development Department (E&D)

10-10-2022By/ Abdelhadi Fahes (FDD Manager)

Exploration & Development Department (E&D)

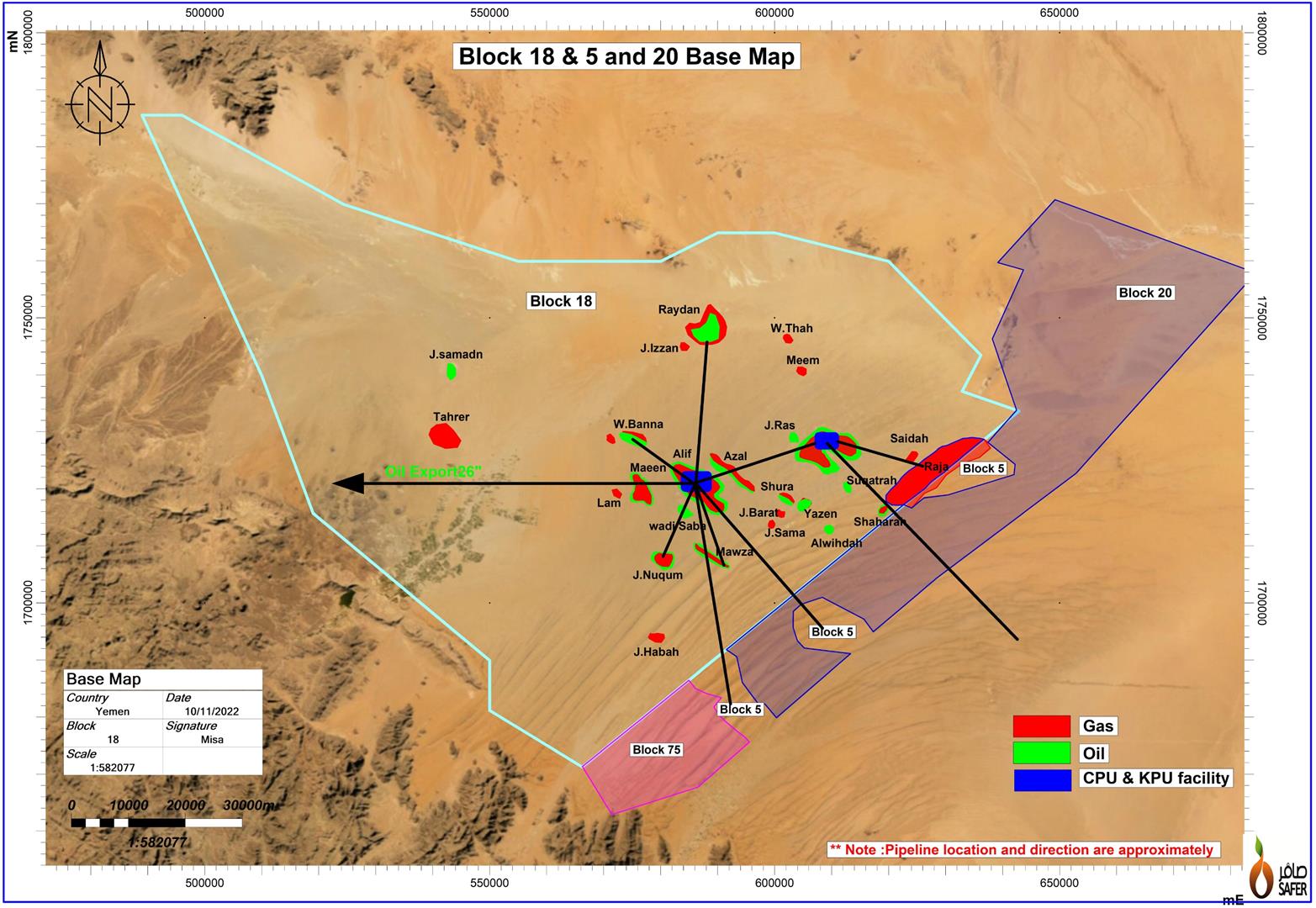

Since the foundation of the Department of Field Development, a qualified technical team of national experts has been prepared. This team includes geophysicists, geologists, Petro physicists, and reservoir and production engineers. The team since then has been effectively applying the most important programs and practical techniques to carry out technical studies (performance simulation models of oil and gas reservoirs) to review the oil and gas reserves available in Block18, develop production and export plans for gas and assessing the effects caused by the losses of crude oil as a result of gas export to Balhaf in January 2009.

On November 15, 2005, SAFER took full responsibility for operations in Block 18 Company receiving oil and gas reserves, containing remaining oil and condensate reserves as confirmed earlier on January 1, 2005 (98 million barrels) according to the D&M certification prepared by the previous operator. Through optimal reservoir management, the Field Development Department was able to add More than 232 million barrels of oil and condensate reserves, in addition to (3 trillion cubic feet of liquefied natural gas).

Regardless of current difficulties and challenges, FDD intends in through the five-year plan for the period 2023 to 2027, fully supported by EGM Eng. Salem Kaiti, to perform numerous projects and studies and introduce new technologies to improve the production performance of wells to raise the daily oil production rate with proper reservoir management. Some of these projects & studies are the following: -

Despite the current difficulties and challenges being faced by Safer Company, the Exploration, and Development Department along with the consistent encouragement and support of the company’s senior management represented by the General Manager, Mr. Salem Kaiti, and through a five year-plan (2023 to 2027), FDD intends to accomplish many projects and studies and introduce modern means and technology to improve the production of wells and monitor the performance of the reservoirs. Below is a list of these means:

- Artificial lift techniques

The most two popular methods of using these mechanisms are either by using the gas lift method or by using electric submersible pumps.

A. Electrical Submersible Pump (ESP) project

In Jan-2014, FDD started using an artificial lift mechanism by ESP pump for the first time in the company’s 35-year history. An ESP pump has been installed on the Wihdah-2 well. That well was not able to produce any more oil due to its down-hole low pressure. The company has succeeded in reproducing from that well using the ESP pump mechanism. Therefore, the same can be applied to many other potentially selected wells.

B. Coiled Tubing Gas Lift (CTGL) project

This is one of the most cost-effective mechanisms used in several countries and it has been proven successful. The gas-Lift method is used to inject gas down the hole to reduce the well’s hydrostatic pressure and create enough pressure to drive oil upward. SEPOC is planning to use this mechanism on a large scale. The company has a massive gas system infrastructure that can provide any needed gas for unloading any needed wells to increase oil production. This proposal is currently under study and evaluation by FDD to be implemented in the next years.

2. Reservoir Surveillance Project using pressure and Saphire temperature measurement tools

On May 2022, FDD started doing a key well survey for key wells using SEPOC’s P&T tools for the first time in the company’s history. This is a major accomplishment by which SAFER company saved all the extra expenses that used to be paid to subcontractors for those services. The data obtained from KWS are used for simulation models QC & remaining reserve estimations & gas injection redistribution plans and reservoir performance evaluations. In addition to that, FDD is planning to extend the use of those tools to do many other jobs i.e., interference, PBU, and PDD tests.

3. SEPOC Simulation Studies

FDD national team successfully built-in house costless dynamic reservoir simulation studies for the biggest and most important fields of SEPOC during 2019-2022 to mimic different reservoirs’ performance and evaluate the remaining oil & gas reserves for production optimization & development plans. Simulation studies for other intermediate fields are ongoing.

4. Long and short-term gas delivery plan (LTGDP)

GDP was early created and frequently revised & updated by the FDD team based on the reservoirs and operations conditions & constraints to evaluate the SEPOC field’s performance and deeply investigate their capabilities to fulfill the long-term gas delivery commitments locally and internationally as per official approved agreements.

5. Short and long-term oil production plans (STOPP & LTOPP) along with future completion plan

FDD team created STOPP & LTOPP to optimize SEPOC production according to current operating conditions and very limited budget due to country crises. These plans are reviewed and modified regularly to concur with the existing operating conditions and constraints.

These plans are reviewed, updated, and modified periodically to comply with the performance and ability of the real oil reservoirs to sustain production at optimum rates predetermined through the executed simulation studies to achieve the highest possible returns for the country taking into consideration the existing operating conditions and constraints.

6- Heavy oil Project:

Alif Heavy oil field was discovered in Yemen in the central part of the Marib-Al Jawf Basin, Block 18 in the early 1980s, in several wells but not tested enough for commercial development. Heavy oil is a critical component of SEPOC’s current and, more importantly, future reserves and production promise in decreasing the API of export crude oil. The heavy oil development project aims to extract heavy oil from the INTRASALT reservoir and will increase the SEPOC oil rate production. The project is still under study.

7-Reprocessing of 3D seismic surveys and seismic inversion on the Marib 3D Area.

SAFER has huge 2D and 3D seismic data acquired from 1980 to 2009, and recently there has been a great development in computer science and artificial intelligence which has encouraged seismic service companies to develop new technologies, workflows, and algorithms in seismic manipulation and seismic inversion.

The main role of the exploration department is to explore new prospects in the formation of Alif, Lam & Basement in the Sabateen Basin, which will add more reserves to Safer and increase oil and gas production. The Exploration Department takes advantage of new technologies to carry out seismic reprocessing and seismic inversion, as work is being done on the inverted project (seismic inversion) on the main area, the Marib 3D Seismic Area. The results are expected to identify many promising areas and structures, which will undergo further evaluation and classification based on the chance of success.

8-Drilling Exploration & Development Wells.

According to the results of seismic Reprocessing, Seismic Inversion, and the results of the wells survey, many studies and reports have been made to evaluate the performance of the reservoirs and update the reservoir models. Accordingly, a plan is determined to drill developmental and exploration wells to be ready as soon as we return to normal operation.